I tried it again, this time with a heat resistant container. I believe the container is PET, so nothing sticks to it. I used pressure sensitive adhesive to attach the parts (same as last time, minus the fire extinguisher) to the container, then sprayed everything (including the inside of the container) with mold release.

I warmed up the Composi-Mold for 2.5 minutes at high in the microwave, and let it cool for a minute. Not all of if melted, but I made more than enough to cover the parts. No disasters this time.

I placed the container in the sink and filed the sink with cold water until the container started to become buoyant. I noticed that the heat (or movement) had loosened one of the heads, which began to float to the top. I used a plastic stick to poke it back down. After about 30 minutes, the Composi-Mold had started to solidify; I pushed the head down into the thicker material at the bottom and this time it held.

The Composi-Mold was allowed 3 hours to cool, or until it no longer was sticky.

Like bugs in amber:

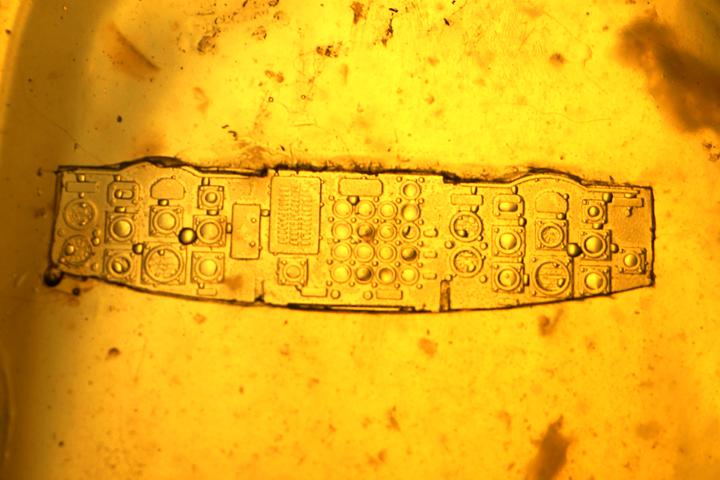

It was pretty easy to remove the Composi-Mold from the container, probably because of the mold release. This is the underside- some material seeped in under the instrument panel, but I removed the excess and threw it back into the Composi-Mold container:

Here's the instrument panel section in detail:

I can't tell if the bubbles are on the surface or just below; I'll find out when I pour some resin. Clearly, some air was trapped in some of the instrument dials.

So far (other than the less than promising first try) I'm really impressed with this material. It's flexible, dense and didn't tear when I pulled out the resin heads. I think in terms of durability, it's similar to the softer silicone rubber mold materials, except it's clear.

Some observations:

1- This stuff gets

hot. Not boiling hot, but hot enough to affect some glues and possibly some heat sensitive materials. The Composi-Mold hold heat very well, so cooling it in a bath is recommended.

2 - The material seems to be somewhat water soluble when liquid - don't get water into the liquid Composi-Mold! It

does have a slight orange or citrus odor, similar to Goo-be-Gone.

3- The liquid Composi-Mold is pretty viscous; moving the container around can cause waves that'll knock your parts off.

4 - Heat resistant containers and surfaces have to be used. Gluing the parts to a thick styrene, MDF or water proofed wood surface should work. Use CA or epoxy. Waxes or modeling clay will not work.

A Legos box around the parts (held in place with a modeling clay dam) may work. The Composi-Mold is very fluid when hot, and it may seep through gaps in the Legos, though.

5 - Use a mold release!

6 - I think it should be easy to pop bubbles that are on the part surfaces. I was too distracted by the floating head to look carefully for bubbles.

7 - it's easy to cut. Since it's transparent, it should reduce the need to make two part molds.

I ran out of time to pour resin - that's next week's project.